Cnc Beam Drill Line Width

Z-Reader Probe- This probe maps the surface's location. It can be operated manually and programmatically. The option is removed from danger and is not active while the cutting process is underway. It can be used for surface mapping or to verify surface at each point before the cutting process begins. It is responsible for initialization, or zeroing the device on the surface at beginning of a program. From there it tracks the difference or accumulates them.

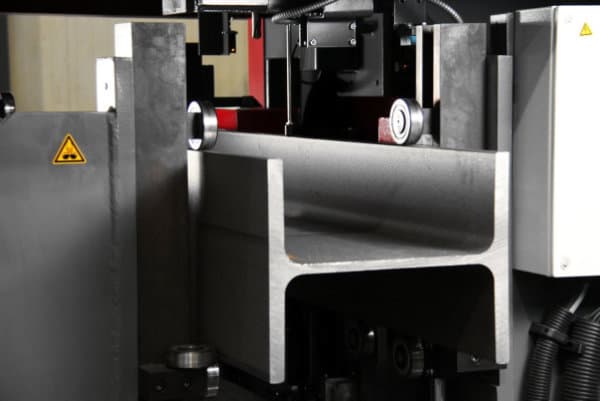

All of our beam drill lines machines are equipped with central lubrication, linear guides, and a tool cooling to ensure smooth operation. There is a four-station tool changer within each coordinate system. This allows the machine to drill and mill, scribe, countersink, or tap as required. Tools can be easily swapped mid-operation. A positive beam positioning arm is attached to the feed conveyor. It allows for more precise positioning of the beam as it moves through the drillline. The rack and pinion system maintains.004" making our steel beam drilllines more accurate than friction roll machines.